Application: In Industrial Construction, Machinery/Rack/Container Manufacturing

Specification: Outer diameter: 10mm*20mm ~ 400mm*600mm

Wall thickness: 0.5mm ~ 20mm

LENGTH: 0.1mtr ~ 18mtr

Standard: ASTM A500, ASTM A53, EN 10210, EN 10219, JIS G 3466, BS 1387, BS 6323

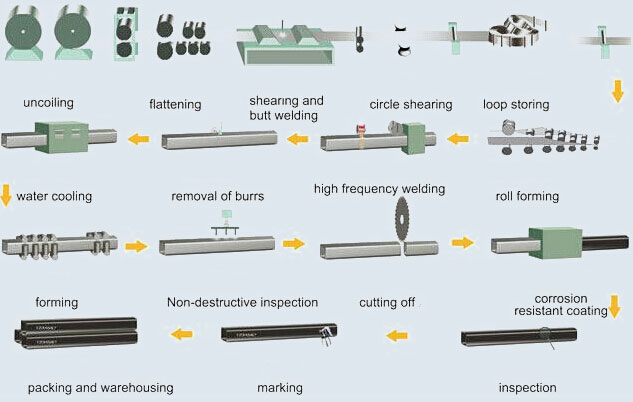

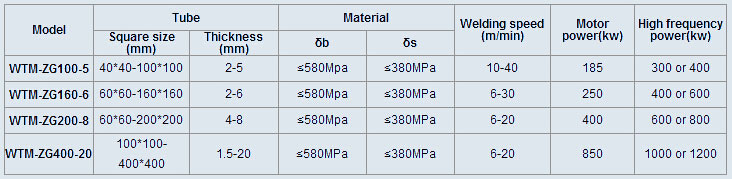

Process Type: Hot Rolled/Hot Expanded,Cold rolled , Annealed(welded), Electric Resistance/High Frequency

End: Square Cut, Burr Removed

Surface: Bare, Black Painting, Lightly Oiled,Black annealing,Galvanized

Packing: Waterproof Paper Wrapped, Steel Strips Bundled, Two Tags on Each Bundle

Sales Contact:

Email:info@sunrisesteelgroup.com

Whatsapp:

Rectangular hollow sections are not as common as UCs and UBs. This is down to the fact that it is much more difficult to bolts it to other beams or to bolt other members to it. RHSs are described by their depth, width and wall thickness. An example is a 200 x 100 x 8 RHS, which is 200 mm deep, 100 mm wide and the wall is 8 mm thick. Hot rolled RHSs are made at the mill as one piece, whereas cold formed RHSs are made of a flat sheet rolled at right angles and welded. It is therefore easy to note the difference, as the cold rolled RHSs have a weld all along its length.

|

Standard |

ASTM A500, EN 10210, EN 10219, JIS G3466, BS 1387, BS 6323 PART5 |

|

Grades |

A500, S185, S235, S235JR, S235 G2H, S275, S275JR, S355JRH, S355J2H, St37, ST52 |

|

Out diameter |

10*20mm - 600*400mm |

|

Wall thickness |

0.5mm - 20mm |

Surface Conditions Special Features

Hot Rolled Hard to find sizes

Hot Rolled Pickled and Oiled Mitre cutting

Cold Rolled High strength steel on request

KleenKote Mult lengths

Standard Corner Radius(Mechanical Sizes:)

| Diameter (inch) | Wall Thickness (inch) |

Radius Tolerance (inch) |

|

1/2 to 1 1/2 |

0.028 |

1/32 to 1/16 |

|

1/2 to 2 1/2 |

0.035 |

1/32 to 1/16 |

|

1/2 to 4 |

0.049 |

3/64 to 5/64 |

|

1/2 to 4 1/8 |

0.065 |

1/16 to 7/64 |

|

3/4 to 4 1/8 |

0.083 |

5/64 to 1/8 |

|

over 4 1/8 to 6 |

0.095 |

3/16 to 5/16 |

|

1 to 4 1/8 |

0.095 |

3/32 to 5/32 |

|

over 4 1/8 to 6 |

0.109 |

3/16 to 5/16 |

|

1 1/4 to 4 |

0.109 |

1/8 to 13/64 |

|

over 4 to 6 |

0.120 |

3/16 to 5/16 |

|

1 1/4 to 4 |

0.120 |

3/16 to 5/16 |

|

over 4 to 6 |

0.134 |

7/32 to 7/16 |

|

2 to 4 |

0.148 |

3/16 to 5/16 |

|

over 4 to 8 |

0.148 |

7/32 to 7/16 |

|

2 to 8 |

0.165 |

1/4 to 1/2 |

|

2 to 8 |

0.180 |

1/4 to 1/2 |

|

2 1/2 to 4 |

0.203 |

5/16 to 9/16 |

|

over 4 to 8 |

0.203 |

5/16 to 9/16 |

|

2 1/2 to 8 |

0.220 |

3/8 to 5/8 |

Max. 3 x Nominal Wall Thickness

|

Mechanical Sizes |

Structural Sizes |

||

|

Largest Nominal Outside Dimension |

Outside Tolerance at all Sides at Corners |

Largest Nominal Outside Dimension |

Outside Tolerance at all Sides at Corners |

|

3/16 to 5/8 |

± 0.004 |

2 1/2 and under |

± 0.020 |

|

over 5/8 to 1 1/8 |

± 0.005 |

over 2 1/2 to 3 1/2 |

± 0.020 |

|

over 1 1/8 to 1 1/2 |

± 0.006 |

over 3 1/2 to 5 1/2 |

± 0.030 |

|

over 1 1/2 to 2 |

± 0.008 |

over 5 1/2 |

± 1% |

|

over 2 to 3 |

± 0.010 |

|

|

|

over 3 to 4 |

± 0.020 |

|

|

|

over 4 to 6 |

± 0.020 |

|

|

|

over 6 to 8 |

± 0.025 |

|

|

Wall Thickness

Mechanical & Structural Sizes: ± 10% of Nominal Wall Thickness

Squareness of Sides

Mechanical Sizes: Max: ± b = c x 0.006"

b = Tolerance for out-of-square

c = Largest external dimension across flats

Structural Sizes: Adjacent sides may deviate from 90 ° by ± 2 °

Maximum Twist (Mechanical & Structural Sizes)

|

Largest Dimension, inches |

Max. Twist*, inches |

|

over 1/2 to 1 1/2 |

0.050 |

|

over 1 1/2 to 2 1/2 |

0.062 |

|

over 2 1/2 to 4 |

0.075 |

|

over 4 to 6 |

0.087 |

|

over 4 to 8 |

0.100 |

Convexity & Concavity(Mechanical & Structural Sizes)

|

Largest Nominal O.D., Inches |

Tolerance ± Inches |

|

2 1/2 and under |

± 0.010 |

|

over 2 1/2 to 4 |

± 0.015 |

|

over 4 to 8 |

± 0.025 |

| Grades |

Chemical |

Physical |

||||||

|

C Max. % |

Mn Max. %Max. % | P Max. % | S Max. % | Cu Max. % |

Tensile strength, min. psi |

Yield strength, min. psi |

Elongation in 2 in. |

|

|

B |

0.26 |

/ |

0.04 |

0.05 | 0.20 |

58,000 |

46,000 |

23 |

|

C |

0.23 |

1.35 |

0.04 |

0.05 | 0.20 |

62,000 |

50,000 |

21 |

www.sunrisesteelgroup.com